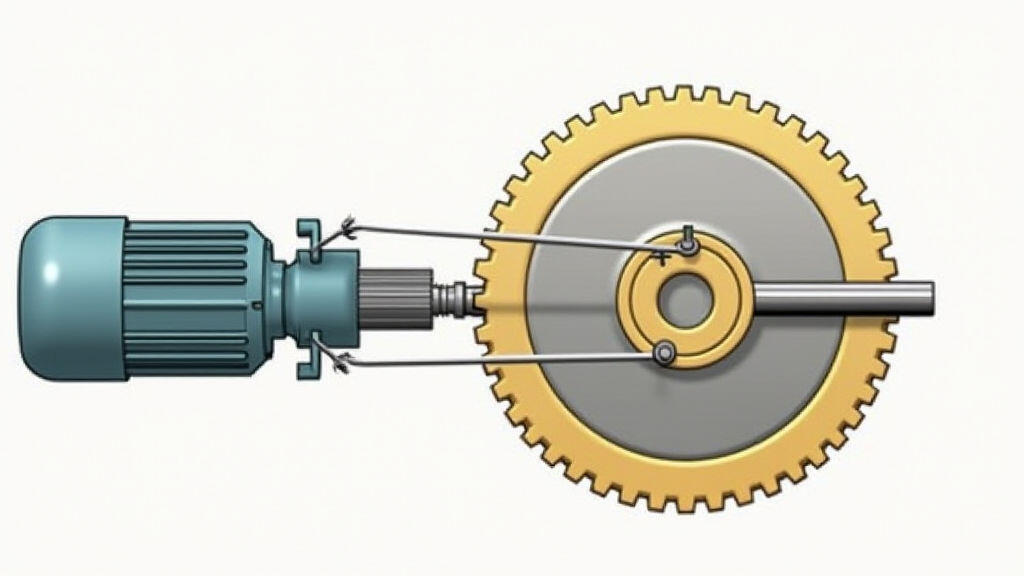

Modern farming is evolving from manual labor to data‑driven, autonomous systems. To keep pace, agricultural machines must receive reliable power and precise motion control. At the heart of many automated equipment upgrades lies the gear motor—a compact, pre‑stepped unit that turns spinning electric current into useful mechanical torque. This article walks through the key considerations, calculations, and best practices for selecting and matching gear motors to your agricultural automation needs.

Unlike simple DC or induction motors, gear motors combine a motor, a gearbox, and a control interface into a single package. They deliver high torque at low speeds, which is ideal for blade drivers, seeders, sprayers, and robotic arms. Benefits include:

Before jumping into math, gather the following specs from the manufacturer catalogue or datasheet:

| Specification | Typical Units |

|---|---|

| Nominal Voltage | 220–480 V AC or 24–48 V DC |

| Speed (at nominal voltage) | rpm |

| Torque (at nominal voltage) | Nm or lb‑ft |

| Power rating | HP or kW |

| Gear ratio | times |

| Efficiency | % |

| Running and continuous current | A |

These values are the foundation for the calculations that follow.

Let’s walk through an example: upgrading a seed spreader that needs to rotate a gear wheel at 250 rpm while pulling 10 kW of power from the tractor’s PTO.

For many seeders, the optimal wheel speed is 250 rpm. This is usually specified by the spreading distance and seed rate calculations.

With a 10 kW PTO, you might only need 8 kW for the spreader (considering friction and safety margin). Convert kW to horsepower: 8 kW ≈ 10.7 hp.

Torque (T) relates to power (P) and speed (ω) by \( P = T × ω \). Convert rpm to rad/s: \( ω = 2π × 250 / 60 ≈ 26.18\, rad/s \). Then \( T = P/ω = 8,000/26.18 ≈ 305\, N·m \).

To achieve 250 rpm from a motor that normally runs at 2,000 rpm, you need a gear ratio of 2,000/250 = 8:1. Check manufacturer catalogs for available ratios around 8:1 with minimal backlash.

Using the mechanical power requirement, the motor should be capable of delivering at least 8 kW. Add a 25% buffer for startup torque spikes, so pick a motor rated for at least 10 kW. Look at the corresponding current draw: at 48 V DC, a 10 kW motor would draw roughly 200 A. Ensure your control cabinet can handle that current.

If the motor’s mechanical efficiency is 90%, the electrical power needed is \( 8,000/0.90 ≈ 8,890\,W \). Adjust your selection accordingly.

Agricultural environments can be dusty and humid. Select a gear motor with a sealed housing (IP65 or higher) and, if possible, active cooling (fan or liquid-cooled jackets).

Each machine has unique demands. Here are quick match notes for common tools:

Always validate your choice against the specific load profile and operating cycle of the machine. A premature motor failure can halt entire operations.

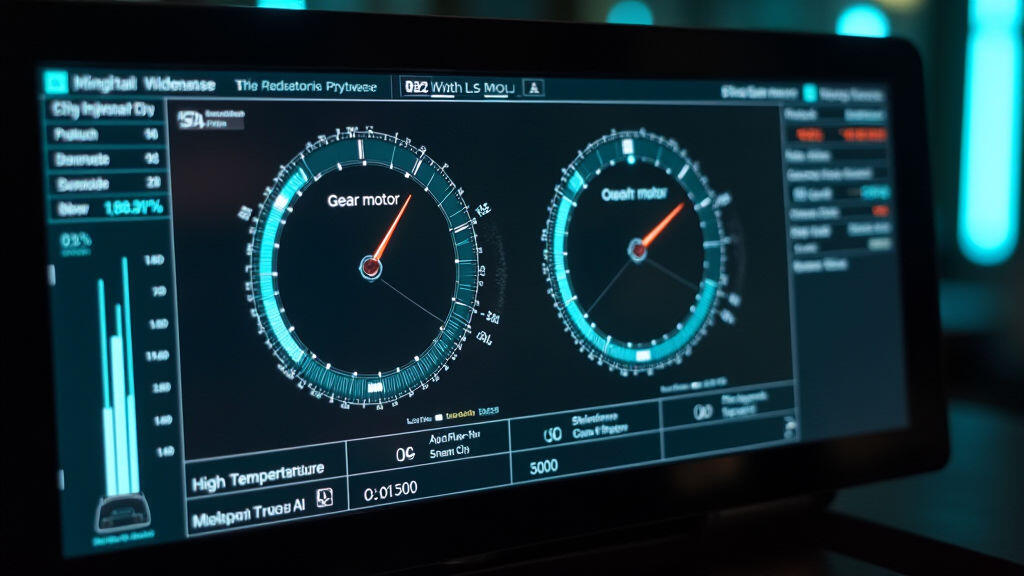

Modern agricultural automation relies on PLCs, microcontrollers, or edge‑processors. Key integration steps:

After installation:

As agriculture embraces the second wave of Industry 4.0, gear motors are evolving too. New developments include:

These trends do not just improve performance—they enable truly autonomous systems that can adjust in real time to soil conditions, weather change, and crop health—all while staying compliant with strict environmental and safety standards.

Choosing the right gear motor for agricultural machinery upgrades involves far more than picking a size that fits. By systematically evaluating torque, speed, power, efficiency, and environmental suitability, and by matching those parameters to the specific demands of seeders, sprayers, or harvesters, operators can unlock reliable automation, higher productivity, and lower operating costs. As new smart motor technologies roll out, the grid of options expands, giving farmers a toolbox ready to meet the 21st‑century demand for precision, sustainability, and resilience. The result is a future where every tractor and field robot can drive efficiently, safely, and autonomously—paving the way for smarter, greener agriculture worldwide.

Leave A Reply

Your email address will not be published. Required fiels are marked